AGEM on iloinen esittämään uusimman tuoteriesinsä Varsinoiduista Sylinteröistä Nestemaisesta Ammoniakista CO2 Argon Nestemaisesta Typpi Nestemaisesta Hiilidioksidesta Dewar-pulloista, jotka on huolellisesti suunniteltu tarjoamaan korkealaatuinen ja luotettava ratkaisu teollisuuden ja kaupallisen käytön tarpeisiin.

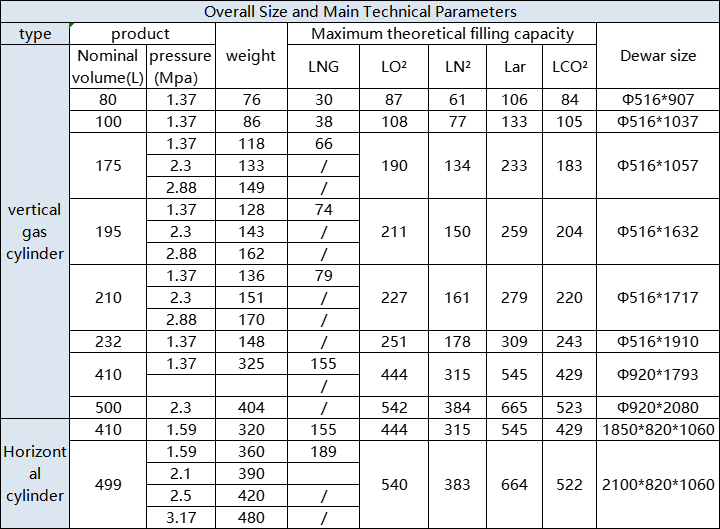

Nämä sylinterit ovat loistavia monien erilaisten sovellusten, kuten liimauksen, leikkaamisen, lääketieteellisen käytön ja lukuisien muiden teollisuusprosessien kannalta. 800L, 1000L ja 600L kokojen ansiosta ne ovat riittävän monipuolisia täyttääkseen mitä tahansa alan tarpeet.

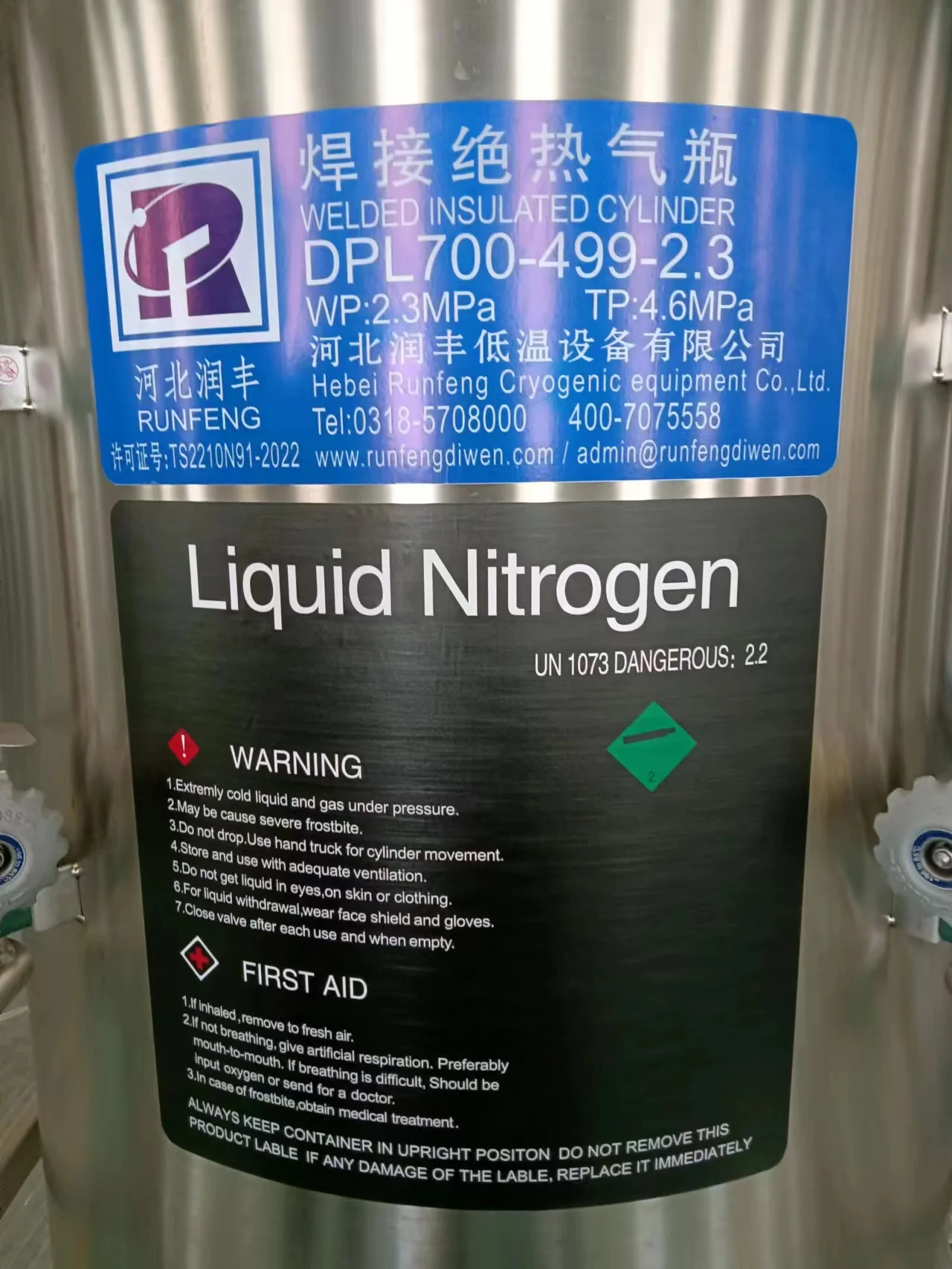

Tankit on rakennettu korkealaadullisista materiaaleista, mikä varmistaa niiden kestovuoren ja luotettavuuden. Ulkoinen sylinteri on tehty kylmällä rullatuolta teräksestä, kun taas sisäinen astia on tehty erityisenkestävästä teräksestä. Kimpusjärjestelmä, joka on kytketty ulko- ja sisäsylinterin välille, tarjoaa erinomaisen lämpöisoloinnin, mikä varmistaa, että nesteesi pysyy halussa olevassa temperatuurissa.

Yksi AGEM:n kimpuskytketyn isoloidun sylinterin nesteenemian CO2 Argonilmanvyöhykkeen hyllypullojen suurimmista etuuksista on niiden siirrettävyys. Pulloja on varustettu pyörillä, jotka tekevät ne helpommin liikuteltaviksi paikkakunnallasi ympärillä. Lisäksi niiden kompakti muoto tarkoittaa, että ne vievät vähemmän tilaa kuin perinteiset kyrogeenijärmekokoonpanot.

Kun kyseessä on täyttäminen tai tyhjentäminen, löydät AGEM:n Lämpöisoloidun Sylinterin Nestemaisiakon CO2 Argon Nikkelin Dewar-pullot helpoksi käyttää. Sylinterin venttiilit varustettu helposti käytettävillä, ergonomisilla kahvoilla. Lisäksi venttiilien kokoja on monia eri vaihtoehtoja, joten saat oikean koon soveltuvaksi tarpeisiisi.

Nämä sylinterit tarjoavat myös alhaiset huoltokustannukset. Vankka rakennus ja korkealaatuiset materiaalit, joita käytetään näiden sylintereiden valmistuksessa, tarkoittaa sitä, että ne toimivat pitkään ja vaativat vähän huoltoa. AGEM:n sylinterit kestää vuosikerrat ja säilyttävät optimaalisen suorituskykynsä vuosikymmeneksi eteenpäin.

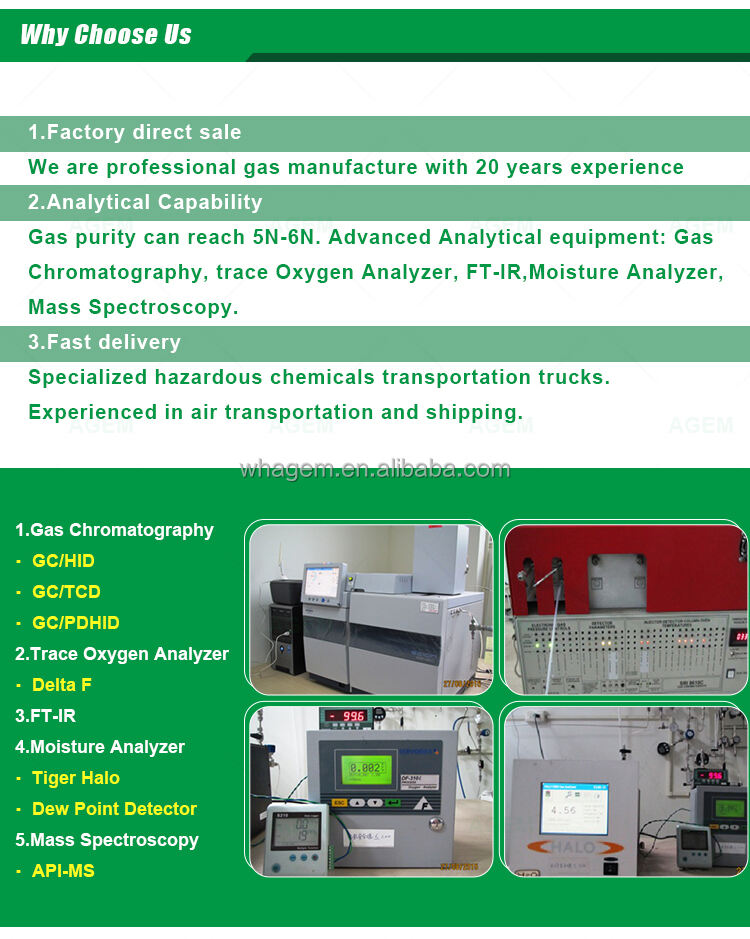

AGEM:n sitoutuminen laatuun ja asiakastyydytykseen tarkoittaa, että voit luottaa AGEM:n liimattuihin eristettyihin syilöihin nestemaisen ammonian, hiilidioksidin, argonin ja nitrogenin kantokuppiin, jotka tarjoavat sinulle tarvittavan suorituskyvyn ja rauhan mieli. Ota yhteyttä tänään saadaksesi lisätietoja siitä, miten voimme auttaa teollisuusprosesseissasi helpommin, tehokkaammin ja taloudellisemmin.

Yläosa on varustettu suojaruudella ja putkistovalvijärjestelmällä. Keskimmäinen pullo on tehty rostivapaasta teräksestä ja sen ympärillä on lämpöisolaatiokerros. Sisällä on rostivapaa terässeinä ja vakuumivälikerros. Supistin: Supistimessa käytetään pyörteitä varustettua lämpövaihtoimia, joka asennetaan pulvon pohjalle paineen lisäämiseksi. Kuitenkin, kun nestetaso pullossa on matala, supistusnopeus on hyvin hitainen. Siksi suosittelemme käyttäjää lisäämään pulvon sisäinen paine ennen käyttöä, jotta seuraavan kerran nesteen vajoamisen aikana pulvon paine pysyy tarpeeksi korkeana. Kaasuvirtavalve: Tämä valve yhdistetään kaasupulvan kaasufaasiavaruuteen. Avaten tämän valven, vapautetaan pulvan kaasua vähentääkseen painetta. Syöttöpoistovalve: Tämä valve hallitsee kylmän nesteen täyttöä. Nestevirtavalve: Tämä valve hallitsee kylmän nesteen virtausta. Supistuspoistovalve: Tämä valve hallitsee supistuskierrosta; avaten sen, painetaan pulvosta. Supistusasetusvalve: Kylmä nestemenee supistimen kautta tämän kautta muuttumassa kaasoksi ja palaa sisäiseen tankkiin, jotta pulvon paine saavuttaa supistusasetusvalven asetetun arvon. Nestetaso mittari: Nestetaso mittari käyttää kapasiteettista nestetaso mittaria. Kapasiteettisia anturit tuottavat sähköisen signaalin, joka on verrannollinen pulvon nesterataan. Nestetaso näyttö laskee signaalin vastaanottamisen jälkeen ja ilmaisee eri nestemäärät prosentteina. Ulkopuiteen ylityspaine suojeleminen tapahtuu vakuumiplugilla. Jos seinä vikaa (johtuen erittäin korkeasta välikerrospaineesta), vakuumiplugi avautuu vapauttaakseen painetta. Jos vakuumiplug vikaa, välikerroksen vakuumi rikkoutuu, ja tällöin huomataan, että ulkopuite "ruijii" ja jäätyy. tietenkin, jää tai kondensaatti putkien lopussa, jotka ovat kytketyt pulvaaseen, on normaalia. Vakuumiplug: Pulvon ulkopuiteen ylityspaine suojeleminen tapahtuu vakuumiplugilla. Jos seinä vikaa (johtuen erittäin korkeasta välikerrospaineesta), vakuumiplugi avautuu vapauttaakseen painetta. Jos vakuumiplug vikaa, välikerroksen vakuumi rikkoutuu. Tällöin huomataan, että kuori "ruijii" ja jäätyy. Luonnollisesti, jää tai kondensaatti putkien lopussa, jotka ovat kytketyt pulvaaseen, on normaalia. (Varoitus: Älä vetä vakuumiplugia koskaan mitenkään olosuhteissa) Dewar-pullon nestetoimitus- ja käyttöprosessi

Ensinnäkin varmista, että varakylpysuuren pääputkijänne on suljettu, avaa kaasuventtiili ja nestemenoventtiili käytettävään teräsylipäässä, sitten avaa vastaava venttiili yhdistelmäkiskon päällyslautaisessa kylpyryhmässä, joka on kytketty teräsylipääseen, ja sen jälkeen avaa vastaava putkien pääventtiili. Lopuksi avaa venttiili höyryttimen syötteessä, ja nestemäinen höyritään höyryttimellä ja toimitetaan käyttäjälle painepasussa säätämisen jälkeen. Nesteen toimittamisessa, jos teräsylipään paine ei ole riittävä, voit avata teräsylipään lisäpainoventtiilin ja lisätä teräsylipään painetta lisäpainojärjestelmällä saadaksesi riittävän nestetoimituspaineen.

Dewarsilla on kaksi pääedullisuutta

Kriojeninen nestemäinen varastointitankki lääketieteelliseen käyttöön Dewar - Ne ovat laajalti käytössä nitrogenin varastoinnissa, kattamassa varsinkin kaasupohjausta, laserleikkausta, krio-saunaa - Happimvarastointia varten, viljelyyn, sairaalan happivaraston tarjoamiseen - LCO2-varastointia varten, laajalti käytetty ruoanpakkauksessa, oluen tehtaassa LNG:n toimittamiseksi, laajalti käytetty yhteisöjen LNG-toimitusjärjestelmässä

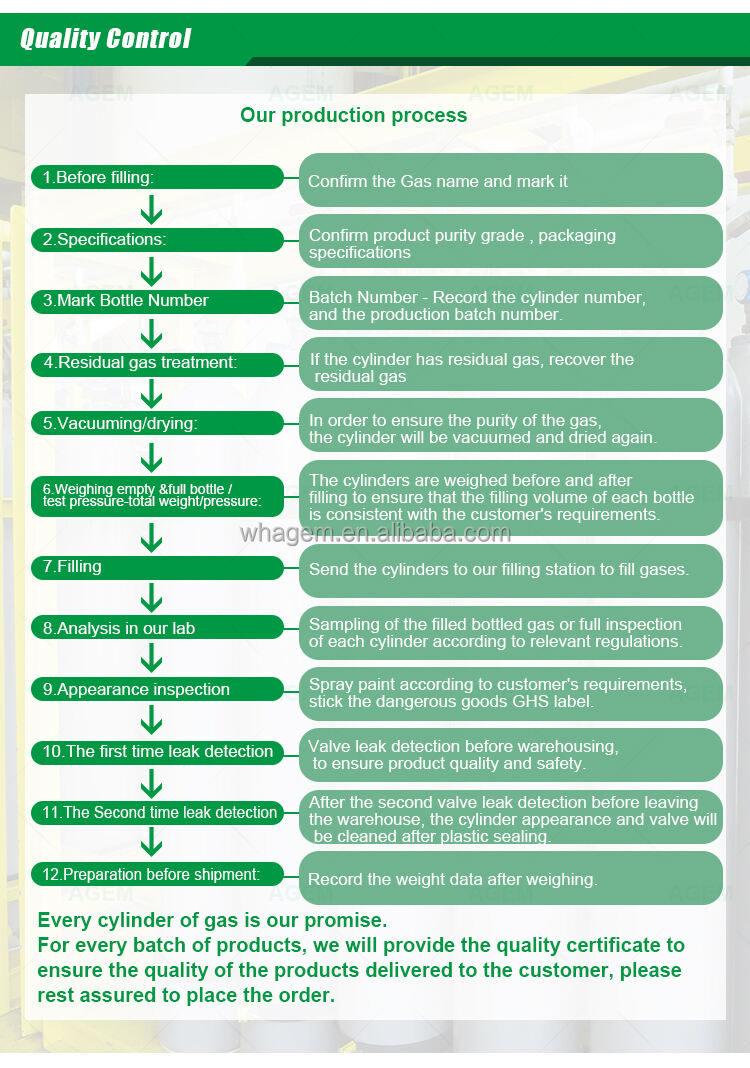

UKK 1. Mitä tarkoittaa MOQ? V: Yhdestä silmukasta alkaen. 2. Mikä on toimitusaika? V: 7-10 päivää Exwork, kun olemme saaneet varannon. Kun olemme tilanne laivan tai ilmatransportin, voimme tietää kokonaista aikaa, joka tarvitaan kuljetukselle asiakkaan maahan. 3. Kuinka kaasun laatu tarkistetaan? V: Ensinnäkin, tiimiemme tekee silmukoille hoitoa (pesu, kuivatus, tyhjentäminen, pumpaus ja korvaus ennen täyttöä varmistaakseen, että silmukan sisäosa on puhtaana ja kuivana). Toiseksi, testaamme käsitellyt silmukat uudelleen varmistaaksemme, että ne ovat puhtaita ja kuivia. Kolmanneksi, analysoimme kaasua sen jälkeen, kun se on täytetty silmukoille, ja annamme COA:n (Analyysisertifikaatti). 4. Voivatko kaikki silmukat olla kierrätettäviä? V: Yleensä liitosilmukoiden käyttöelämä on yli 20 vuotta. Kertakäyttöiset silmukat voidaan käyttää vain kerran. 5. Voimmeko lähettää silmukoita takaisin Kiinaan ja täyttää niitä uudestaan kaasulla? V: Kyllä, kun yrityksesi on käyttänyt kaiken kaasun, voit lähettää tyhjiä silmukoita takaisin ja täyttää ne uudestaan kaasulla. Sinun täytyy vain ilmoittaa meille ennen vientiä, ja me hoitamme silmukoitten merkintöjen käsittelyn Kiinassa. 6. Mitkä silmukoiden ja venttiilien standardit ovat saatavilla? V: Silmukat DOT-3AA ISO9809, GB5099, TC-3AAM. EN1964, KGS. VENTTIILI: DISS, CGA, DIN, BS, AFNOR, JIS. 7. Voinko tehdä LCL-maksut muun tavallisen lastini kanssa? V: Tuotteidemme kuuluu DG-lastin luokkaan 2.2 ja niiden pitää kuljettaa DG-lastina. Jos ne lähetetään tavallisena lastina, se on laiton. Meidän täytyy tilata DG-lasti laivoilta. Jos sinulla on muita tavallisia tuotteita, voit lisätä ne lastiin ja lähettää sen DG-lastina.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SK

SK

SL

SL

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LO

LO

LA

LA

MI

MI

MR

MR

MN

MN

NE

NE

UZ

UZ