AGEM is trots om sy nuutste reeks Gesoldeerde Geïsoleerde Silinder Vloeistof Ammoniak CO2 Argon Stikstof Dewar-bottles aan te bied, wat met groot sorgsaamheid vervaardig is om 'n hoëkwaliteit, betroubare oplossing vir industriële en kommersiële gebruik te verskaf.

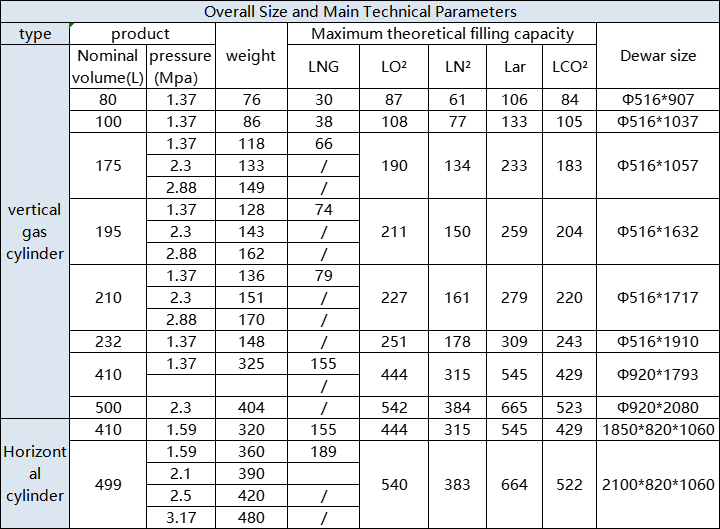

Hierdie silinders is perfek vir 'n wye verskeidenheid toepassings, soos skweer, sny, mediese gebruik en ongetelle ander industriële prosesse. Die 800L, 1000L en 600L groottes maak hulle versoepelend genoeg om die behoeftes van enige bedryf te voldoen.

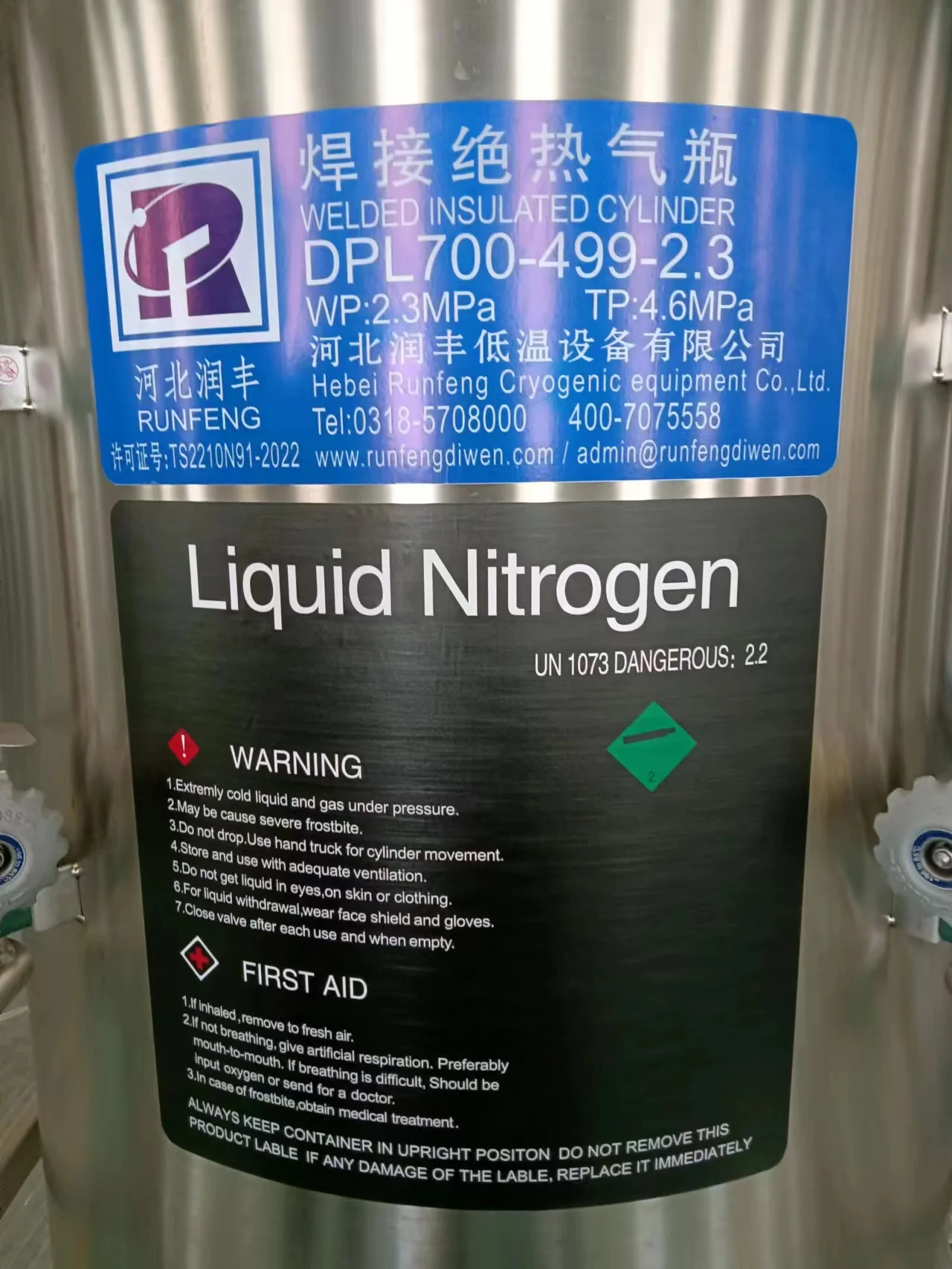

Die tanks word met hoë-kwaliteitsmateriale gebou, wat verseker dat hulle duurzaam en betroubaar is. Die buitensilinder word gemaak van kou-gedraaisteel, terwyl die binnekamer van spesiaal weerstandende staal gemaak word. Die gesoldeerde isolasie-stelsel tussen die buite- en binnesilinder verskaf uitstekende termiese isolasie, wat verseker dat jou vloeistof by die gewenste temperatuur bly.

Een van die grootste voordele van AGEM’s Gesoldeerde Geïsoleerde Silinder Vloeistof Ammoniak CO2 Argon Stik Dampfles Bottles is hul draagbaarheid. Die bottels word uitgerus met rolwiele, wat dit maklik maak om hulle rondom jou plaas te beweeg. Daarnaast beteken hul kompakte ontwerp dat hulle minder ruimte inneem as tradisionele kriogeniese bergingstelsels.

Wanneer dit om volsuil of ontlading gaan, sal jy vind dat die AGEM se Gesoldeerde Geïsoleerde Silinder Vloeiammoniak CO2 Argon Stikstof Dewar-bottels ongelooflik maklik te gebruik is. Die silinderkleppies is uitgerus met maklik te gebruik, ergonomiese handvatsies. Boonop kom die kleppies in 'n verskeidenheid groottes, so dat jy die perfekte pas sal kan kry vir jou toepassing.

Nog 'n voordeel van hierdie silinders is hul lae onderhoud vereistes. Die stadige konstruksie en hoë-kwaliteit materiaal wat in die produksie van hierdie silinders gebruik word, beteken dat hulle lanklaasende prestasie lewer en minimaal onderhoud vereis. AGEM se silinders het 'n lange lewensduur en is in staat om hul optimale prestasie vir jare te kom te behou.

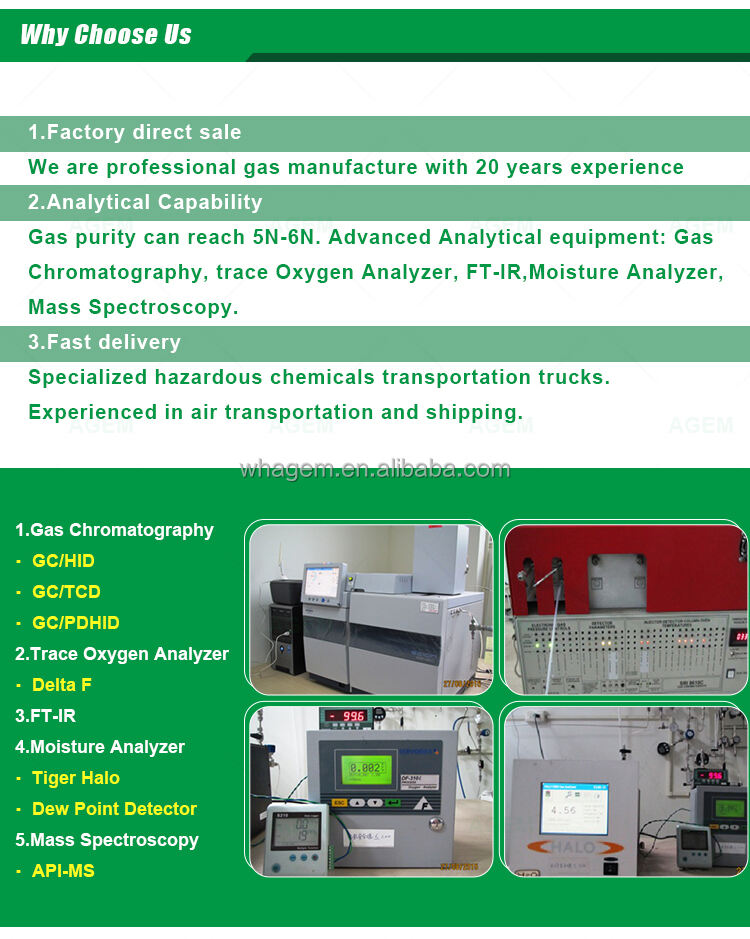

AGEM se toewyding tot kwaliteit en klantevoldoening beteken dat jy op AGEM se Gesoldeerde Geïsoleerde Silinder Vloeiammoniak CO2 Argon Stikstof Dewar Bottles kan vertrou om jou die prestasie en rus wat jy nodig het te verskaf. Neem vandag nog kontak met ons op om meer te leer oor hoe ons jou industriële prosesse makliker, doeltreffender en koste-effektiewer kan maak.

Die bo-geparte het 'n beskermende ring en 'n buislynklepstelsel. Die middelbottel het 'n roestvrystaaikas en 'n warmteisolatieskikker. Daarbinne is daar 'n roestvrystaailiner en 'n vakuumtussenlaag. Superlader: Die superlader gebruik 'n vynvormige warmteswapper en word by die onderkant van die bottel geïnstalleer om die druk binnein te verhoog. Toe die vloeistofvlak in die bottel laag is, is die versnelingspoed baie stadig. Dus word dit aanbeveel dat die gebruiker voor gebruik die druk binnein verhoog sodat die druk binnein die vereistes kan voldoen wanneer die vloeistofafvoerklep gebruik word. Gasfaseklep: Hierdie klep is met die gasfase ruimte van die gaskilinder verbonden. Maak hierdie klep oop om die gas in die silinder uit te laat om die druk te verminder. Inlatingsklopklep: Hierdie klep word gebruik om die invulling van koue vloeistof te beheer. Vloeistofuitvoerklep: Hierdie klep word gebruik om die uitset van koue vloeistof te beheer. Verhogingsklopklep: Hierdie klep word gebruik om die verhogingskring te beheer, maak die klep oop om die bottel te druk. Verhogingsreguleringsklep: Die koue vloeistof gaan deur hierdie klep na die superlader en word gas, wat terugkeer na die binnentank sodat die druk binnein die ingestelde waarde van die verhogingsreguleringsklep bereik. Vloeistofvlakmeter: Die vloeistofvlakmeter gebruik 'n kapasitiewe vloeistofvlakmeter. Die kapasitiessensor genereer 'n proporsionele elektriese sein volgens die hoogte van die vloeistof in die bottel. Die vloeistofvlakweergawetabel konverteer die sein nadat dit die elektriese sein ontvang, en wys die hoeveelheid van verskillende vloeistowwe in persentasietalle. Beskerming teen oordruk word deur 'n vakuumplug bewerkstellig. As die liner lek (wat lei tot super hoë tusselaagdruk), sal die vakuumplug oopgaan om die druk af te laat. Indien die vakuumplug lek, sal die vakuum van die tusselaag gebreek word, waarna gevind sal word dat die behuising "sweat" en frost. Natuurlik is frost of kondensering op die einde van die buis wat aan die bottel gekoppel is normaal. Vakuumplug: Beskerming teen oordruk word deur 'n vakuumplug bewerkstellig. As die liner lek (wat lei tot super hoë tusselaagdruk), sal die vakuumplug oopgaan om die druk af te laat. In geval van lek van die vakuumplug sal die vakuum van die tusselaag gebreek word. Op dié tyd kan "sweating" en frosting van die skil gevind word. Natuurlik is frost of kondensering op die einde van die buis wat aan die bottel gekoppel is normaal. (Waarskuwing: Trek die vakuumplug onder geen omstandighede nie uit) Vloeistofvoorsiening en gebruik proses van Dewar bottel

Eerstens, maak seker dat die hoofpyplynvalve van die reserfiondergroep gesluit is, maak die gasvalve en vloeistof-uitvoervalve op die staelcilinder wat gebruik word oop, maak dan die ooreenstemmende valve op die koppingskiet van die cilindergroep wat aan die staelcilinder gekoppel is oop, en maak dan die ooreenstemmende pyplyn-hoofvalve oop. Valve. Ten slotte, maak die valve by die invoer van die verdampaar oop, en die vloeistof sal deur die verdampaar verdamp word en na die gebruiker verskaf word nadat dit deur die drukregulator gereguleer is. Wanneer vloeistof verskaf word, as die druk van die staelcilinder nie genoeg is nie, kan jy die versterkervalve van die staelcilinder oopmaak, en die staelcilinder versterk deur die versterkingstelsel van die staelcilinder, sodat jy genoeg vloeistofverskaffingsdruk kry.

Dewars het twee hoofvoordele

Kriogeen Vloeistofsilinder bergingstank vir mediese gebruik Dewar - Hulle word wydverspreid gebruik vir stikstof berging, vir Smeed, laser sny, vir Cryosauna -Vir suurstof berging, vir boerdery, vir Hospitaal suurstofvoorsiening -vir LCO2 berging, wydverspreid gebruik in voedselvriesing, vir bierfabriek Vir LNG-voorsiening, wydverspreid gebruik in gemeenskaplike LNG-voorsieningstelsel

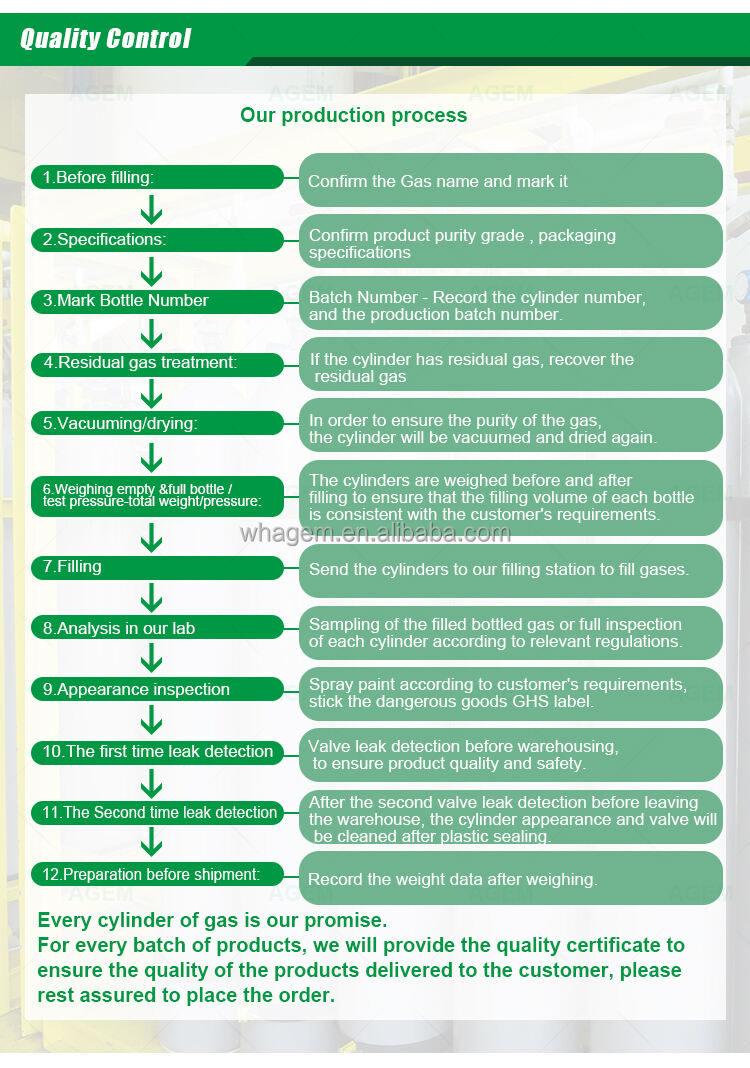

Veelgestelde vrae 1. Wat is die MOQ? A: Van een cilinder af. 2. Wat is die lewer tyd? A: 7-10 dae Exwork nadat ons die voorschot ontvang, Nadat ons die skip of lugvervoer bestel, kan ons die totale tyd vir lewering na die klant se land bepaal. 3. Hoe kontroleer ons die gas kwaliteit? A: Eerstens, ons span sal cilinder behandeling doen (reiniging, droging, vakuum, pomping en vervanging voor die invulling van gas om seker te maak dat die cilinder van binne rein en droog is). Tweedens, ons sal die behandelde cilinders weer toets, om seker te maak dat die binneste van die cilinder rein en droog is. Derdens, ons sal die gas analiseer nadat dit in die cilinders ingevul is en die COA (Sertifikaat van Analise) verskaf. 4. Kan al die cilinders hergebruik word? A: Gewoonlik is die werkslewe van seemlose staalcilinders meer as 20 jaar. Die eenmalige cilinders kan slegs een keer gebruik word. 5. Kan ons cilinders terugstuur na China en die gas herspan? A: Ja, wanneer jou maatskappy uit gas raak, kan jy die leeg cilinders terugstuur en die gas herspan. Jy moet ons net voor jou uitvoer informeer, ons sal die douanevormslag van die cilinders in China hanteer. 6. Cilinders en Klep standaard beskikbaar? A: Cilinder DOT-3AA ISO9809, GB5099, TC-3AAM. EN1964, KGS KLEP: DISS, CGA, DIN, BS, AFNOR, JIS. 7. Kan ek LCL met my ander algemene vrakte doen? A: Ons produkte behoort tot vlak 2.2 DG goederen en moet saam met DG goederen vervoer word, indien as algemene goederen vervoer word, is dit onwettig, ons moet DG goederen van die vervoermaatskappy bestel, as jy ander algemene produkte het, kan jy dit byvoeg aan die laai en as DG goederen stuur.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SK

SK

SL

SL

UK

UK

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LO

LO

LA

LA

MI

MI

MR

MR

MN

MN

NE

NE

UZ

UZ