Siz allaqachon eshitgan bo'lishingiz mumkin bo'lgan bitta brend AGEM hisoblanadi, u Argon CO2 silindirlarini ishlab chiqaradi. Ular savdo maqsadiga muvofiq va foydali silindirlar hisoblanadi. Ushbu silindirlar ikki ta metall qism orasida rost va xavfsiz ulanish yaratish uchun poyasadordan foydalaniladi. Argon gaz poyasa joyida havoga yaqinlashishdan himoyalab olib atmosferani neutral holatga keltiradi. Ushbu himoya qatori metallni ayibga ochirmaydi. Shuningdek, CO2 gazining asosiy vazifasi AGEMning "helium laser" mahsuloti kabi poyasadorga va metall orasida stabillashgan arkni rivojlantirish va saqlashdir. geliy lazerni . Ushbu jarayonning doimiy bo'lishi poyasning rost va doimiy ekanligini ta'minlaydi.

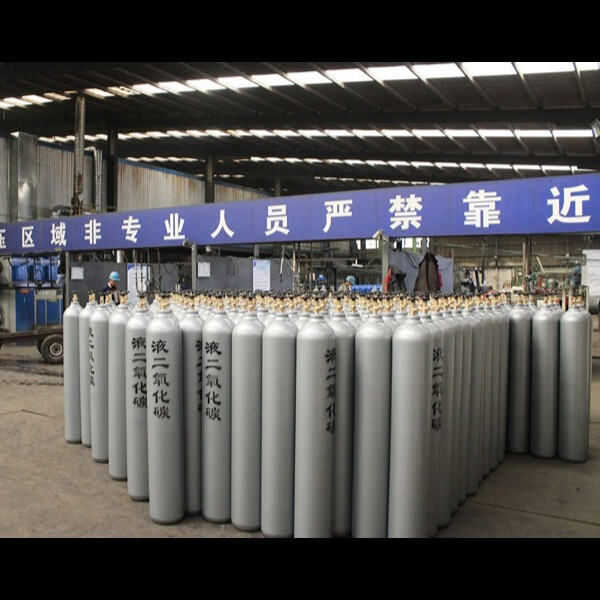

Argon CO2 silindirlari: Katta qismi professional窦 suvdlar ishlarida ushbu turdagiidan foydalanishni taqqoslaydi. Bunda asosiy sabab shu silindirlarning butun suvdashish jarayonida osonlikni taqdim etishi. Suvdlar suvdashish oson bo'lganda yaxshiroq suvlaydi. Agar qaz to'g'ri bo'lmasa, masalan, bu muammo bo'lishi mumkin. Ammo Argon CO2 silindirlari bilan bunday muammolar namunisi kam, birgalikda gross geldikda geliy tanki aGEM tomonidan ta'minlangan. Agar suvdlar ushbu muammolardan xolda bo'lsa, ular oxirida pul va vaqt saqlashga yordam bera oladi — umumiy efeksiyliliklarni yaxshilaydi.

MIG suvdashishda Argon CO2 silindirlarining istalgan ravishda foydalanish kerak, demak, shu turi suvdashishda AGEM mahsuloti kabi juda effektivdir maxsus gaz yetkazib beruvchisi mIG punoni orqali o'tadigan turli xil metallik to'yinlar mavjud. Keyinchalik ushbu to'yin quvvat manbaga ulanadi, bu esa puna yordam beradi. Ushbu qaz Argon deyiladi va u metallik silindir ichidagi metalla muhofaza qilish uchun ishlatiladi, uni zayiflashishi oldidan saqlaydi. U oxidasini oldini oladi, ya'ni havo metall bilan reaksiya etganida metall zayiflashi jarayoni. Aksincha, CO2 qazi istiqbolli pulka saqlashda yordam beradi. Bu shuningdek, barcha punalarning yaxshi va boshlang'an bo'lishiga sabab bo'ladi. Natijada, bu juda robushtir punani hosil qiladi. Ular og'ir foydalanish uchun mo'ljallangan, bu esa ushbu turli pунalarning bir necha turdagi loyiha uchun mukammal ekanligiga sabab.

To'g'ri hajmdagi Argon CO2 silindirni tanlash sizning pulkangiz uchun katta ahamiyatga ega, shu jumladan ham nitrous Oxide aGEM tomonidan ishlab chiqilgan. Sizga qancha hajmdagi silindir kerak ekanligi, sizning qanchalik puldor izohini bajarish va suv bilan ishlash uchun metal quyiqlarining hajmi asosida belgilanadi. Agar siz ko'p puldor qilishni xohlasangiz yoki kengroq metal quyiqlari bilan ishlayotgan bo'lsangiz, katta hajmdagi silindir tanlash juda yaxshi variant bo'ladi. Katta silindirda ko'proq gaz saqlanadi, shuning uchun ish jarayonida gaz tugamaydi. Bu sizni ishni to'xtatmasdan davom ettirishga yordam beradi.

Argon CO2 silindiridan foydalanish muvaffaqiyatli puldor qilish uchun qo'shimcha amallarni talab qilsa ham, AGEMning "tank argon" mahsuloti kabi, bu amallar shart emas. аргон танка birinchi sirt, silindirni yoqilgan holda turib turganligiga doim ishonch hosil qiling. Bu esa uni tushmasligi uchun xavfsiz joyda bo'lishini anglatadi. Silindirni ishlatmayotganda valvani yoping. Bu gazning xavfsizligini ta’minlaydi va avariyalarni oldini olishga yordam beradi. To‘g‘ri debit va bosim qiymatlarini sozlash ham poyasadagi ishlab chiqarish amaliyotida muhim hisoblanadi. Notsoring sozlamalar sizga narsalar yomon chiqishi imkoniyatini beradi. Va oxirgi, lekin eng asosiy nuroqqa qo‘l ko‘zingizni doim ishlatishingiz kerak. Ular suv to‘qimi va issiq metalldan sizi himoyalaydigan asosiy narsalar.

AGEM har kanday suvliq va qazlarni, masalan, suvliq oksigen, argon, karbon dioksid, nitrogen va nitrous oksid kabi past temperaturadagi maddalarini saqlash uchun turli xil kriogenik silindirlar taklif qiladi. Eng yaxshi performansni ta'minlash uchun importlangan valvular va texnikalar ishlatiladi. Qazni saqlash uchun qurilmalar ishlatiladi va gaz fazasi bo'ylab bosim ortishi holatida avvalgi ehtiyot sifatida ishlatiladi. Ikki xavfsizlik valvuli to'g'ri ishlash uchun mo'ljallangan xavfsizlikni ta'minlaydi. Bizda umumiy super sochilgan suvliqlarni saqlash uchun turli xil kriogenik silindirlar mavjud: To'liq hajm: 80L/100L/175L/195L/210L/232L/410L/500L/1000L Ish bosimi: 1.37MPa/2.3MPa/2.88MPa/3.45MPa Ichkidan tank dizayn temperaturasi: (-196) Shell tank dizayn temperaturasi: 50oC+20oC Isolatsiya: ko'p qattali shuvingli bo'sh joy isolatsiyasi Saqlangan o'rmon: LO2, LN2, LAr, LCO2, LNG

AGEM har xil mijozlarning maxsus qo‘ng‘iroqlariga ega bo‘lishini tushunadi, masalan, kalibratsiya qazlari kabi maxsus qazlarga doir. Biz mijozlarimizning xususi talablarini qanoatlantirish uchun shaxsiylashtirilgan yechimlarni taqdim etishimiz mumkin. Agar siz maxsus tozalik darajasini, tsilindrning hajmini yoki paketlash variantlarini kerak bo‘lsangiz, AGEM mijozlar bilan ishlab chiqish orqali mahsulotlaringizni aniq speksifikatsiyangizga moslashtirishi mumkin. Shu darajadagi shaxsiylashtirish, sizga kerakli kalibratsiya qazlarini va kerakli tsilindrngizni olishga yordam beradi, umumiy efeksiyani va performansni oshiradi. AGEMning ko‘p turdagi mahsulotlari bor, faqat kalibratsiya qazlari emas. AGEM katalogida hidrokarbongazlar, halokarbonlar, kimyoviy qazlar va nardorga qazlar ham joylashgan. Bu sizning kerakli qazingizni ta'minlash uchun AGEMga ishonishingiz mumkinligini anglatadi.

Argon co2 silindir tanklari otkazishlari eng katta muammolardan biri bo'lishi mumkin. Sifatni ta'minlash uchun otkazishlardan qo'lga kirish uchun beshdan ortiq martada tekshiramiz. Kompaniyamiz to'liq ishlab chiqarish va tekshirish qatorini, shuningdek, sifatni boshqarishning asosiy tartibi va mustaqil saqlash xizmati tizimi orqali mijozlarimizga eng yaxshi mahsulot va to'liq xizmatlarni taqdim etishda davom etadi. Sifat va mijoz xizmatidan qandaydir guruhimiz juda kuchli ekspertlarning jamoasi sizni yordam berish va talablaringizni bajaringiz uchun doimiy ravishda tayyor. 24/7 xizmat bizni ajralib turuvchi narsa hisoblanadi. Har kun, har bir kun davomida siz uchun bu yerda yotganman.

AGEM 25 yildan ko'p vaqtdir Taivan buyicha faoliyat yuritadi. Biz shu sohada keng tarqalgan iqtisodiy va ishlab chiqarish (R va D) bilimi mavjud va 6 turdagi mintaqa bo'yicha maxsus massalik, kalibratsiya qazlari sohasida ajralib turuvchi bilimni taqdim etishimiz mumkin. Taivan - Kaohsiung shahri (markaz, R va D markazi) Hindiston - Mumbai, Vadodara, Koyimbatur, Pune, Bengaluru, Dilli Xitoy - Uhan Orta Sharq - Dubay (BAA) va Saudiya Arabistoni Buyuk Britaniya - Kembridj Qaz yechimlarimiz texnik maslahatberish, qurish va komissiya berish, namuna sinov, paketlash va yetkazib berish, chizma dizayni, ishlab chiqarishdan iborat.