Daha önce duymuş olabileceğiniz bir marka olan AGEM, Argon CO2 silindirleri üreten bir markadır. Bu silindirler, kaynaklama amacıyla kullanılan çok önemli ve faydalı silindirlerdir. Kaynakçılar, bu silindirleri iki metal parçası arasında dayanıklı ve güvenli bir bağlantı oluşturmak için kullanır. Argon, kaynaklama alanını hava yakınlığından koruyarak çevreyi nötralize eder. Bu koruma tabakası, metale zarar verilmesini engellemek için kritik importance taşır. Ayrıca, CO2 gazı, AGEM'in ürettiği ürün gibi, kaynak tabancası ve metalden oluşan sabit bir yayın gelişmesine ve sürdürülmesine yardımcı olur. helyum laseri . Bu sürekli çizgi, kaydın sert ve kalıcı olduğundan emin olmak için gereklimdir.

Argon CO2 silindirleri: Çoğu profesyonel kaynakçı işlerini bu türden yapmayı tercih eder. Bunun en büyük nedeni, bu silindirlerin tüm kaynaklama sürecini kolaylaştırmasıdır. Kaynakçılar, kaynağı daha kolay olduğunda daha iyi çalışır. Gaz uygun değilse, örneğin, bu durum bir sorun haline gelebilir. Ancak, Argon CO2 silindirleriyle böyle sorunlar nadirdir, beraberinde toplu helyum tankı aGEM tarafından sağlanır. Kaynakçılar bu engellerden uzak tutulduğunda, sonunda para ve zaman kazandırabilirler — genel verimliliklerini artırarak.

MIG kaynağı için Argon CO2 silindirlerinin kullanımı harikadır, bu nedenle bu tür kaynağı ile çok etkilidir, AGEM'in ürünleri gibi özel gaz tedarikçisi . MIG torchu aracılığıyla kaynakta kullanılan bir tür metal tel vardır. Daha sonra bu tel, kaynağı kaynak işlemine yardımcı olan bir güç kaynağına bağlanır. Bu gaz Argon olarak adlandırılır ve metali silindir içinde hasar görmesini önlemek için korur. Yaptığı şey oksidasyonu önlemektir, yani hava metal ile reaksiyon gösterdiğinde meydana gelen süreçtir ve bu da metali zayıflatabilir. CO2 gazı ise istikrarlı bir kaynak arkı korumak için yardımcı olur. Bu aynı zamanda tüm kaynağın pürüzsüz ve kontrol altındaki anlamına gelir. Sonuç olarak, bu son derece dayanıklı bir kaynak sağlar. Ağır kullanım için tasarlanmışlardır, bu da bu tür kaynakların birçok farklı proje için mükem

Kaynak işiniz için doğru boyuttaki Argon CO2 silindirini seçmek büyük bir rol oynar, aynı şekilde kıtros Oksit aGEM tarafından geliştirildi. Ne kadar büyük bir silindir needing yapman gerekecek, planladığın kaynak miktarına ve kaynaklamayı planladığın metallerin parçalarının boyutuna bağlı olacaktır. Eğer fazla kaynağa ihtiyacınız olacağını veya daha kalın metal parçalarıyla çalışıyorsanız, daha büyük bir silindir seçmek daha iyi bir seçenektir. Büyük bir silindir daha fazla gaz alır, böylece çalışırken tükenecek riski olmaz. Bu, çalışmanızı kesintisiz olarak sürdürmenize yardımcı olur.

Bir Argon CO2 silindiri kullanmak ekstra adımlar gerektirebilir ancak AGEM'in sunduğu ürün gibi kaynak işleminizin başarılı olması için gerekli olan adımları takip etmelisiniz argon tankı öncelikle, silindirin sıkıca monte edildiğinden emin olun. Bu, silindirin devrilmemesi için güvenli bir yerde olması demektir. Silindiri kullanmadığınızda vanayı kapatın. Bu, gazın güvenliğini sağlar ve kazaları önler. Kaynak işlemlerinde doğru akış hızı ve basınç değerlerini ayarlamanın da büyük önemi vardır. Uyumsuz ayarlar, fukaranın kalitesinin kötüleşmesine neden olabilir. Ve son olarak, koruyucu ekipmanlarınızı her zaman giydiğinizden emin olun. Bu, kaynak esnasında etrafınıza uçan şimşekler ve sıcak metalden korunmanıza yardımcı olur.

AGEM, kalibrasyon gazları gibi özel gazlara ilişkin farklı müşterilerin farklı ihtiyaçlara sahip olduğunu biliyor. Müşterilerimizin gereksinimlerine uygun özelleştirilmiş çözümler sunabiliriz. Belirli bir saflik düzeyi, silindir boyutu veya ambalaj seçeneği gerektiği zaman, AGEM müşterilerle işbirliği yaparak ürünlerini belirli gereksinimlerinize uyacak şekilde özelleştirebilir. Bu tür bir özelleştirme, size özel uygulamanız için kalibre edilebilen en uygun gaz silindirlerini sağlamayı sağlar ve genel etkinliği ve performansı artırır. AGEM'in ürün yelpazesi yalnızca kalibrasyon gazlarına sınırlı değildir. AGEM'in kataloğu, Karbonhidrat Gazları, Halokarbonlar, Kimyasal Gazlar ve Nadir Gazlar içerir. AGEM'in ihtiyacınız olan gazı bulacağınızdan emin olabilirsiniz.

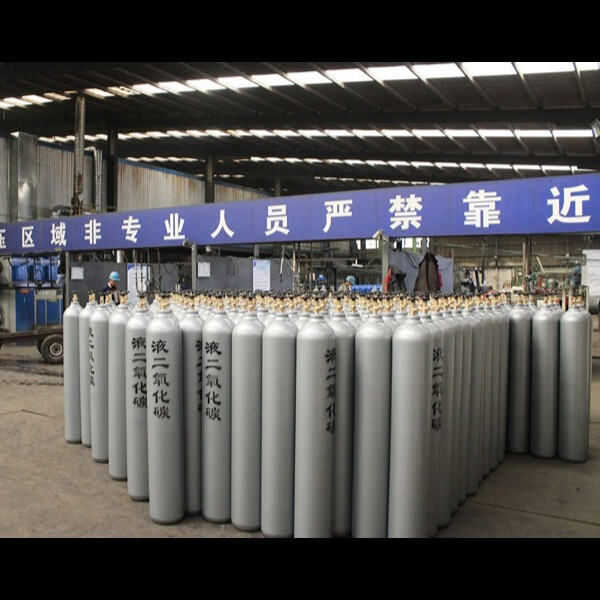

Argon-CO2 tüpleri için gaz sızıntısı, başlıca sorunlardan biridir. Bu nedenle, kaliteyi sağlamak amacıyla sızıntı testlerini beş kezden fazla gerçekleştiriyoruz. Tamamlayıcı bir üretim hattına, sıkı bir kalite kontrol sistemine ve kapsamlı bir satış sonrası hizmet paketine sahibiz. Müşterilerimizin en yüksek kalitede ürünleri almasını sağlıyoruz. Mükemmellik ve müşteri hizmetlerine verdiğimiz bağlılıkla gurur duyuyoruz. Yetenekli ekibimiz, sizlere her zaman yardımcı olmak ve en iyi hizmeti, en yüksek memnuniyet düzeyiyle sunmak için hazır durumdadır. Bizi diğerlerinden ayıran özellik, haftanın yedi günü, günde 24 saat hizmet vermeye hazır olmamızdır. Hafta boyu, tüm zaman dilimlerinde size yardımcı olmaya hazırız.

AGEM, bu alanda 25 yıldan fazla zengin R ve D deneyimi olan, küresel olarak 6 farklı bölgede Özel Elektronik Toplu, Kalibrasyon ve Özel gazlar konusunda eşsiz bir uzmanlığa sahip Taiwanda bulunan bir Gaz Üretim ve R ve D tesisi dir: Taiwan - Kaohsiung Şehri (Genel Merkez, R ve D Merkezi) Hindistan - Mumbai, Vadodara, Coimbatore, Pune, Bengaluru, Delhi Çin - Wuhan Orta Doğu - Dubai ve Suudi Arabistan Birleşik Krallık - Cambridge Gaz çözümlerimiz, Teknik Danışmanlık, Derleme ve Komisyonlama, Örnek Testleri, ambalaj ve sevkiyat, Çizim Tasarımı, Üretim içerir.

AGEM, sıvı oksijen ve argon gibi süper soğutma sıvıları ve gazlarını soğutmak için geniş bir dizi kriyojenerik silindir sunmaktadır. Ayrıca karbon dioksit, azot ve nitröz de tutabilir. Maksimum performansı sağlamak için ithal vanalar ve aletler kullanırız. Gaz tasarruf cihazlarını kullanın ve faz uzayında fazla basınçlı gaz kullanımına öncelik verin. Çift güvenlik vanaları güvenli işlem için sağlam bir güvence sağlar. Günlük hayatta kullanılan süper soğuk sıvıları barındıracak şekilde tasarlanmış geniş bir dizi kriyojenerik silindir sunuyoruz. Tam Hacim: 80L/100L/175L/195L/210L/232L/410L/500L/1000L İşlem Basıncı: 1.37MPa/2.3MPa/2.88MPa/3.45MPa İç Tank Tasarım Sıcaklığı: +196 Kabuk Tank Tasarım Sıcaklığı: 20oC+50oC Yüzeyleme: Çok Katmanlı Sarılmış Boşluk ile yalıtım Depolama Ortamı: LO2, LN2, LArLCO2, LNG